When your vehicle’s MOT test reveals a severely deteriorated CV boot, this seemingly minor defect signals a potentially serious issue brewing within your car’s drivetrain system. The constant velocity joint boot serves as the unsung hero protecting one of your vehicle’s most critical transmission components, yet many drivers remain unaware of its vital function until problems arise. This protective barrier, though relatively inexpensive to replace, guards against catastrophic joint failure that could leave you stranded and facing repair bills exceeding £1,500.

Understanding what severe CV boot deterioration means for your vehicle requires examining both the immediate implications and the progressive damage that follows when this protective seal fails. Modern vehicles rely heavily on these flexible joints to transfer power smoothly from the transmission to the wheels, accommodating the constant movement of suspension systems and steering inputs that occur during normal driving conditions.

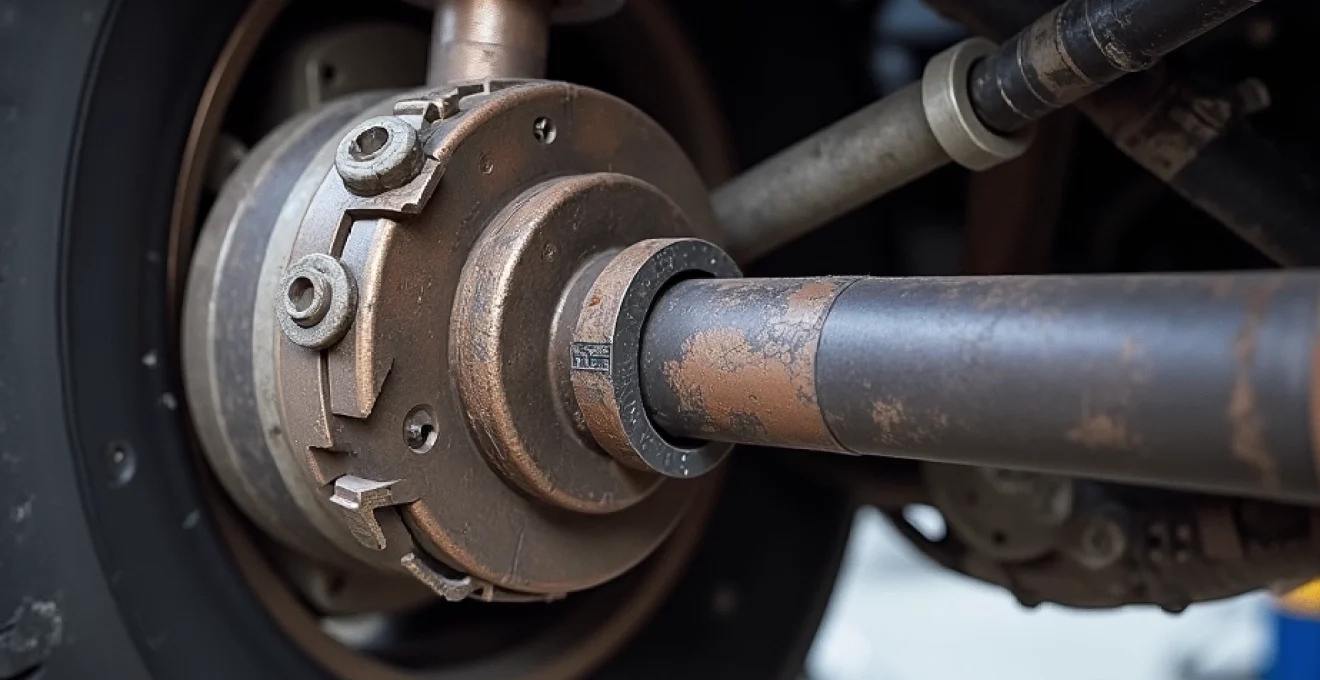

CV joint boot function and construction in drive shaft assemblies

The CV joint boot represents a marvel of automotive engineering simplicity, designed to perform multiple critical functions simultaneously within the drivetrain assembly. These accordion-shaped protective covers encapsulate the constant velocity joints, creating a sealed environment that maintains optimal operating conditions for the precision-engineered components within. The boot’s primary responsibility involves containing specialised grease that lubricates the joint’s moving parts whilst preventing the ingress of water, dirt, and road debris that would rapidly destroy the finely machined surfaces.

Thermoplastic elastomer boot materials and heat resistance properties

Modern CV boots utilise advanced thermoplastic elastomer compounds specifically formulated to withstand the extreme operating conditions found in automotive drivetrains. These materials must demonstrate exceptional flexibility across temperature ranges from -40°C to +120°C, maintaining their sealing properties throughout thousands of compression and extension cycles. The molecular structure of these polymers provides superior resistance to ozone degradation, a common failure mode in older rubber boot designs that would crack prematurely when exposed to atmospheric pollutants.

Premium boot materials incorporate carbon black reinforcement and anti-oxidant additives that extend service life significantly beyond standard rubber alternatives. High-performance thermoplastic elastomers can maintain their flexibility and sealing integrity for over 100,000 miles under normal operating conditions, though severe driving environments may reduce this lifespan considerably.

Grease containment systems in rzeppa and tripod joint configurations

The grease containment strategy varies significantly between different CV joint designs, with Rzeppa joints requiring approximately 120-150 grams of specialised lithium complex grease, whilst tripod configurations typically contain 80-100 grams. This lubricant serves multiple purposes beyond simple friction reduction, acting as a corrosion inhibitor and heat transfer medium that maintains optimal operating temperatures during high-load conditions. The boot’s internal volume must accommodate grease expansion during operation whilst preventing air pocket formation that could compromise lubrication effectiveness.

Grease formulations for CV joints incorporate molybdenum disulfide or graphite additives that provide boundary lubrication protection during extreme loading conditions. These solid lubricant particles create a protective film on metal surfaces that prevents metal-to-metal contact even when the primary grease film breaks down under pressure.

Boot clamp mechanisms: oetiker vs traditional worm drive systems

CV boot retention systems represent a critical engineering challenge, requiring secure sealing under dynamic loading conditions whilst accommodating thermal expansion and contraction cycles. Oetiker clamps utilise a single-ear design that provides consistent clamping force through a mechanical advantage system, creating uniform pressure distribution around the boot’s circumference. This design eliminates the pressure variations common with traditional worm drive clamps that can create localised stress concentrations leading to premature boot failure.

Traditional worm drive systems, whilst less expensive, present several disadvantages including uneven clamping pressure and the potential for over-tightening that can damage the boot material. The screw mechanism in worm drive clamps can also loosen over time due to vibration, gradually reducing sealing effectiveness and allowing contaminant ingress.

Contaminant barrier performance against road salt and debris

The CV boot’s effectiveness as a contaminant barrier directly impacts joint longevity, with even microscopic breaches in the seal allowing destructive elements to enter the joint assembly. Road salt presents particularly aggressive corrosion challenges, creating an electrolytic environment that accelerates metal degradation within the joint. Modern boot designs incorporate multiple sealing lips and barrier systems that maintain protection even when minor surface damage occurs.

Particle filtration performance becomes critical in off-road applications where fine sand and grit can act as abrasive compounds, rapidly wearing joint surfaces when contamination occurs. The boot’s accordion structure must flex continuously without creating channels that allow particle infiltration, requiring precise engineering of fold geometry and material properties.

Identifying severe CV boot deterioration symptoms

Recognising the early warning signs of CV boot deterioration enables preventative maintenance that can save hundreds of pounds in repair costs. Severe deterioration typically manifests through multiple symptoms that progressively worsen as the protective seal continues to fail, ultimately compromising the joint’s integrity and threatening complete drivetrain failure.

Visible cracking patterns in neoprene and silicone boot materials

Visual inspection reveals characteristic cracking patterns that indicate different failure mechanisms within the boot material. Circumferential cracks typically result from repeated flexing cycles that fatigue the polymer structure, whilst longitudinal splits often indicate excessive stretching during suspension articulation. Ozone cracking appears as a network of fine surface fissures that gradually penetrate deeper into the material, eventually creating pathways for grease leakage and contaminant ingress.

Age-related deterioration in neoprene boots manifests as surface hardening accompanied by loss of flexibility, making the material brittle and prone to catastrophic splitting under normal operating loads. Silicone boots demonstrate superior longevity but can suffer from oil contamination that causes swelling and eventual seal failure around clamp areas.

Grease leakage detection around wheel wells and suspension components

Grease leakage provides the most definitive evidence of boot compromise, appearing as distinctive patterns on suspension components, brake assemblies, and wheel wells. Fresh leakage typically presents as clean, light-coloured grease deposits, whilst older leaks accumulate road dirt creating dark, sticky contamination that can affect brake performance when it migrates onto disc surfaces.

The distribution pattern of leaked grease often indicates the specific location and severity of the boot failure. Spray patterns radiating outward from the joint suggest catastrophic boot rupture, whilst localised deposits near clamp areas typically indicate gradual seal degradation or improper installation.

Clicking noise diagnosis during Lock-to-Lock steering manoeuvres

Audible symptoms represent advanced stages of CV joint deterioration where internal damage has already occurred due to inadequate lubrication or contaminant infiltration. The characteristic clicking sound during full-lock turns indicates worn ball bearings or race surfaces within Rzeppa joints, typically occurring when contamination has removed the protective grease film allowing metal-to-metal contact.

Diagnostic procedures involve conducting low-speed turns with full steering lock whilst listening for rhythmic clicking that correlates with wheel rotation. The frequency and intensity of these sounds indicate the severity of internal damage, with constant clicking suggesting imminent joint failure requiring immediate replacement.

Vibration analysis through constant velocity joint operation

Vibration symptoms typically manifest during acceleration or deceleration phases when higher torque loads stress the compromised joint components. These vibrations transmit through the steering system and can be felt through the steering wheel, particularly during moderate acceleration from standstill. The frequency characteristics often correlate with vehicle speed, distinguishing CV joint vibration from wheel balance or tyre-related issues.

Frequency analysis reveals that CV joint vibrations typically occur in the 10-25 Hz range during normal driving speeds, creating a distinctive rumbling sensation that intensifies under load. This differs significantly from engine-related vibrations or transmission issues that typically manifest at different frequency ranges.

Root causes of accelerated CV boot degradation

Understanding the underlying mechanisms that accelerate CV boot deterioration enables better preventative maintenance strategies and helps identify vehicles at higher risk of premature failure. Multiple environmental and operational factors contribute to boot degradation, often working synergistically to reduce service life significantly below manufacturer expectations.

Ozone cracking in EPDM rubber compounds under UV exposure

Atmospheric ozone presents one of the most significant threats to rubber-based CV boot materials, initiating chemical reactions that break down polymer chains and create microscopic cracks. These reactions occur even at low ozone concentrations typical of urban environments, with the process accelerated by UV radiation and elevated temperatures. EPDM rubber compounds demonstrate superior ozone resistance compared to natural rubber, but extended exposure eventually overwhelms even advanced formulations.

The crack propagation mechanism begins at the boot’s outer surface where ozone concentration is highest, gradually penetrating deeper into the material structure. Antiozonant additives provide temporary protection but become depleted over time, leaving the base polymer vulnerable to continued degradation. This process explains why CV boots often fail suddenly after years of apparently normal service life.

Temperature cycling effects on boot flexibility and seal integrity

Extreme temperature variations create thermal stress cycles that gradually degrade boot material properties through repeated expansion and contraction. During cold weather operation, boot materials become less flexible, increasing stress concentrations at fold lines and clamp areas. Conversely, high-temperature operation can cause temporary softening that reduces sealing effectiveness and accelerates chemical degradation processes.

Temperature cycling between summer and winter extremes can reduce CV boot service life by up to 40% compared to moderate climate operation, particularly in materials that lack appropriate plasticiser additives.

Mechanical stress from suspension travel and articulation angles

The constant flexing motion required during normal vehicle operation subjects CV boots to millions of compression and extension cycles throughout their service life. Suspension travel during cornering, braking, and acceleration creates complex loading patterns that stress different areas of the boot structure. Vehicles with sport-tuned suspensions or those frequently driven on rough roads experience accelerated boot wear due to increased articulation angles and higher loading frequencies.

Fatigue crack initiation typically occurs at high-stress concentration points where the boot folds create sharp bends in the material. Once initiated, these cracks propagate rapidly under continued cyclic loading, eventually creating pathways for grease leakage and environmental contamination.

Chemical degradation from de-icing agents and petroleum products

Road de-icing chemicals create particularly aggressive environments for CV boot materials, with chloride-based compounds causing accelerated degradation through chemical attack on polymer structures. These chemicals also increase the corrosivity of any water that penetrates compromised seals, accelerating internal joint corrosion once contamination occurs. Petroleum-based contaminants from oil spills or leaking components can cause boot swelling and softening that compromises sealing effectiveness.

Modern de-icing formulations often incorporate corrosion inhibitors that reduce metal damage but may actually accelerate polymer degradation through complex chemical interactions. This creates a challenging environment where boot materials must resist multiple aggressive compounds simultaneously whilst maintaining flexibility and sealing properties.

Progressive joint damage from compromised boot protection

When CV boot protection fails, a cascade of destructive processes begins within the joint assembly that progressively worsens until complete failure occurs. Understanding this degradation sequence helps explain why seemingly minor boot damage can lead to major repair requirements and emphasises the importance of prompt corrective action when deterioration is detected.

The initial phase of joint damage typically begins with grease contamination rather than complete loss, as road dirt mixes with the existing lubricant to create an abrasive compound. This contaminated grease accelerates wear on precision-machined joint surfaces, creating metal particles that further increase the abrasive effect. Simultaneously, moisture ingress begins corrosion processes that create surface pitting and geometric changes in critical load-bearing areas.

As contamination levels increase, the protective grease film breaks down completely in high-load areas, allowing direct metal-to-metal contact between joint components. This contact creates heat that further degrades any remaining lubricant whilst generating additional wear particles. The joint’s precision clearances, typically measured in hundredths of millimetres, quickly exceed acceptable tolerances as wear accelerates exponentially.

Research indicates that CV joints can experience wear rates up to 50 times normal levels once significant boot compromise occurs, with complete failure often following within 5,000-10,000 miles depending on driving conditions.

The final stage involves catastrophic joint failure where worn components can no longer maintain proper contact patterns under load. Ball bearings may fracture, race surfaces may crack, or cage components may fail completely, resulting in immediate loss of power transmission. This type of failure often occurs suddenly and without warning, potentially creating dangerous driving situations where steering control is compromised.

Diagnostic procedures for CV joint assembly assessment

Professional assessment of CV joint condition requires systematic inspection procedures that evaluate both visible boot condition and internal joint integrity. Modern diagnostic approaches combine visual inspection techniques with functional testing methods that can detect early-stage problems before complete failure occurs, enabling cost-effective repairs when joint replacement might otherwise be necessary.

Initial assessment begins with thorough visual inspection of boot condition, examining for obvious splits, cracks, or grease leakage that indicate immediate problems. However, subtle deterioration often requires more detailed examination using inspection mirrors and lighting to access areas obscured by suspension components. Inspectors should pay particular attention to fold lines where fatigue cracking typically initiates and clamp areas where seal integrity is critical.

Functional testing involves operating the steering through full lock-to-lock cycles whilst listening for characteristic clicking noises that indicate internal joint damage. This testing should be conducted at various speeds and load conditions to identify problems that may not manifest under all operating conditions. Professional diagnostic equipment can detect vibration frequencies and amplitude changes that indicate developing problems before they become audible.

Advanced diagnostic procedures may include grease analysis where samples can be examined for metal particles, moisture content, and contamination levels that indicate joint condition. This analysis provides valuable information about internal wear rates and helps determine whether simple boot replacement is sufficient or complete joint renewal is required.

Replacement strategies and preventative maintenance protocols

Effective CV boot replacement strategies require careful assessment of joint condition, proper material selection, and meticulous installation procedures that ensure maximum service life. The decision between boot-only replacement versus complete joint renewal depends on several factors including contamination levels, joint condition, and cost-effectiveness considerations that vary significantly between vehicle applications.

When boot damage is detected early, before significant grease loss or contamination has occurred, boot-only replacement often provides a cost-effective solution. This approach requires complete disassembly of the joint to remove contaminated grease, thorough cleaning of all components, and careful inspection for wear or damage that might indicate the need for complete replacement. Fresh grease must be applied according to manufacturer specifications, with particular attention to proper filling techniques that avoid air pocket formation.

Complete joint replacement becomes necessary when inspection reveals significant wear, contamination damage, or geometric changes that compromise performance. Modern replacement joints often incorporate improved boot materials and designs that offer superior longevity compared to original equipment. However, proper installation remains critical, with incorrect assembly procedures potentially causing premature failure even with high-quality components.

Preventative replacement of CV boots at 60,000-80,000 mile intervals can prevent joint damage and reduce total maintenance costs by up to 60% compared to waiting until failure occurs.

Preventative maintenance protocols should include regular boot inspection during routine service intervals, with particular attention during winter months when harsh environmental conditions accelerate deterioration. Vehicle owners who frequently drive in severe conditions including off-road use, construction sites, or areas with heavy salt usage should consider more frequent inspection intervals. Early detection and prompt corrective action represent the most effective strategies for maintaining drivetrain reliability whilst minimising repair costs.

Professional mechanics utilise specialised diagnostic equipment including vibration analysers and stethoscopes to detect subtle changes in joint operation that might not be apparent to untrained personnel. These tools can identify developing problems at frequencies beyond human hearing range, enabling predictive maintenance schedules that prevent unexpected failures. Advanced diagnostic protocols also incorporate road testing under various load conditions to evaluate joint performance during actual operating scenarios.

Temperature measurement using infrared thermometers can reveal abnormal heat generation within joints, indicating inadequate lubrication or excessive internal friction. Joints operating at temperatures exceeding 80°C under normal driving conditions typically require immediate attention, as this thermal signature suggests imminent failure. Documentation of diagnostic findings enables tracking of deterioration rates and helps establish optimal replacement intervals for similar vehicle applications.

Replacement strategies and preventative maintenance protocols

Developing effective replacement strategies requires balancing immediate repair costs against long-term reliability considerations, particularly when dealing with high-mileage vehicles where multiple drivetrain components may be approaching end-of-life simultaneously. The economics of CV joint maintenance become more complex when considering labour costs, as accessing joint assemblies often requires substantial suspension disassembly that can account for 60-70% of total repair expenses.

Boot-only replacement strategies prove most cost-effective when implemented before significant contamination occurs, typically saving 40-50% compared to complete joint replacement costs. However, this approach requires rigorous assessment of joint condition, including measurement of internal clearances and evaluation of grease contamination levels. Mechanics must consider the potential reputational risk of recommending boot replacement when joint condition is marginal, as subsequent joint failure could necessitate repeat repairs within short timeframes.

Complete drivetrain overhaul strategies make economic sense for vehicles with multiple failing components, particularly when combined with other major maintenance procedures such as transmission service or suspension renewal. This approach enables bulk purchasing of components and reduces labour costs through consolidated work procedures. Fleet maintenance operators often find this strategy most effective for vehicles approaching major service milestones where comprehensive inspection reveals multiple pending failures.

Industry analysis indicates that proactive CV joint replacement during scheduled maintenance intervals can reduce total ownership costs by up to 35% compared to reactive repair strategies, particularly for commercial vehicle applications where downtime costs are significant.

Preventative maintenance protocols must account for varying operating environments and usage patterns that significantly affect component longevity. Vehicles operating in coastal environments with high salt exposure require more frequent inspection intervals, typically every 12,000-15,000 miles compared to the standard 20,000-mile intervals appropriate for moderate climates. Similarly, vehicles used for towing or frequent off-road operation experience accelerated boot wear that justifies reduced service intervals and upgraded component specifications.

Documentation systems play a crucial role in effective preventative maintenance, enabling tracking of component performance across vehicle populations and identification of emerging failure patterns. Modern fleet management systems incorporate predictive analytics that can forecast component replacement requirements based on historical data, operating conditions, and accumulated mileage. This data-driven approach enables optimised parts inventory management and scheduling of maintenance activities during planned downtime periods.

Training programmes for maintenance personnel should emphasise proper diagnostic techniques and installation procedures that maximise component longevity. Incorrect installation represents a leading cause of premature CV boot failure, with improper clamp installation and inadequate grease application accounting for significant warranty claims. Regular refresher training ensures technicians remain current with evolving materials technology and manufacturer-specific installation requirements that vary between vehicle applications.

Quality assurance protocols should include post-installation inspections that verify proper boot positioning, clamp torque specifications, and grease containment. These procedures help identify installation errors before vehicles are returned to service, reducing callback rates and maintaining customer confidence in repair quality. Photographic documentation of installation procedures provides valuable training resources and helps establish consistent quality standards across multiple technicians and service locations.