Volvo’s brief foray into V8 engine territory remains one of the most fascinating chapters in the Swedish automaker’s history. Between 2005 and 2011, Volvo produced just two models equipped with their unique 4.4-litre V8 powerplant: the XC90 SUV and the S80 executive sedan. This departure from Volvo’s traditional four and six-cylinder philosophy represented a bold attempt to compete directly with premium German and American manufacturers who dominated the luxury V8 segment. The collaboration between Volvo, Ford, and Yamaha resulted in an engineering marvel that delivered 311-315 horsepower whilst maintaining the brand’s commitment to safety and refinement. Today, these V8-powered Volvos have achieved cult status amongst enthusiasts, representing the final era of large-displacement engines before the industry’s decisive shift towards electrification and downsizing.

Volvo’s V8 engine development history and technical specifications

The development of Volvo’s first and only V8 engine emerged from the company’s acquisition by Ford Motor Company in 1999. Ford recognised that Volvo needed a powerful engine option to compete effectively in the lucrative North American luxury SUV market, where eight-cylinder powerplants were considered essential for premium positioning. The project began in 2001 with the specific goal of creating a transversely-mounted V8 that could fit into Volvo’s existing platform architecture whilst delivering the performance and refinement expected from luxury buyers.

B8444S 4.4-litre V8 engine architecture and performance metrics

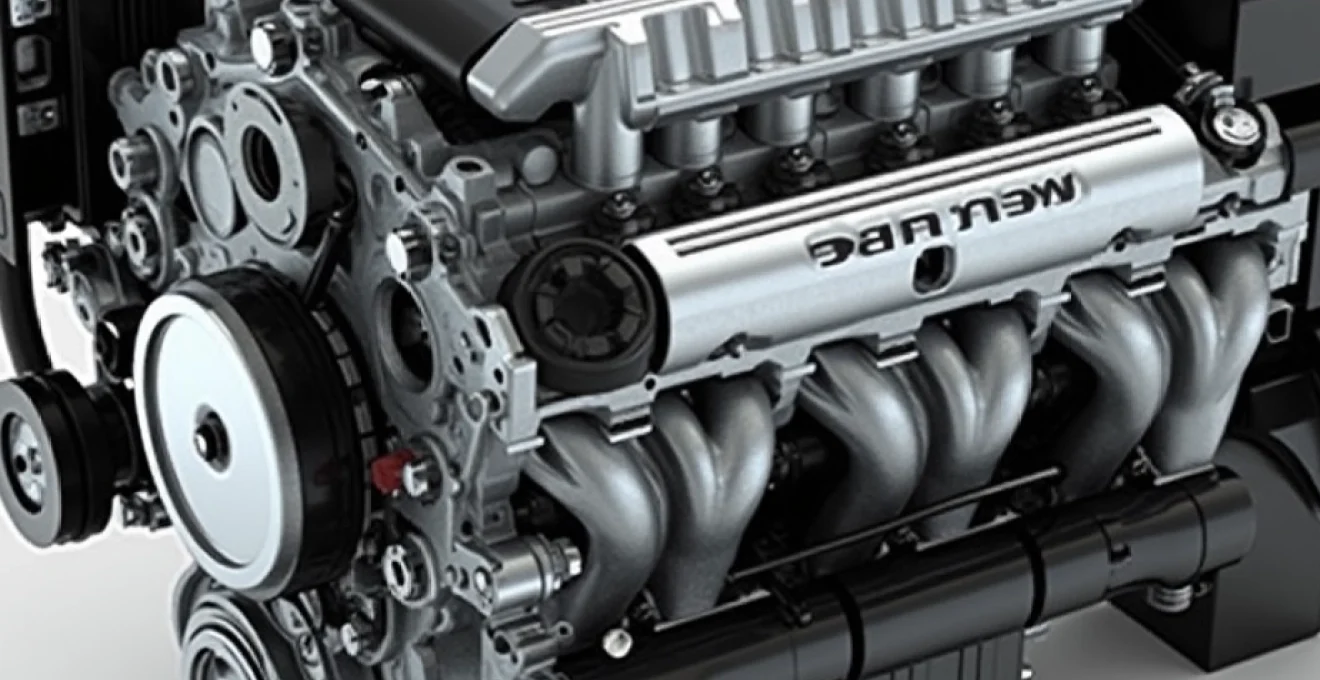

The B8444S designation identified Volvo’s revolutionary 4.4-litre V8, which featured an unconventional 60-degree bank angle rather than the traditional 90-degree configuration typical of most V8 engines. This compact design enabled transverse mounting in front-wheel-drive platforms, making it suitable for Volvo’s P2 platform vehicles. The engine produced 311 horsepower in XC90 applications and 315 horsepower in the S80, with peak torque figures reaching 325 lb-ft at 3,900 rpm.

The performance characteristics of the B8444S impressed automotive journalists and customers alike. The XC90 V8 could accelerate from 0-60 mph in approximately 7.1 seconds , whilst the lighter S80 V8 achieved the same sprint in under 6.5 seconds. These figures placed both vehicles firmly in premium territory, competing directly with established rivals such as the BMW X5 4.4i and Mercedes-Benz ML500.

Yamaha-volvo V8 collaboration and engineering partnership

The unusual partnership between Volvo and Yamaha Motor Corporation brought together Swedish automotive expertise and Japanese precision engineering. Yamaha, renowned for its motorcycle engines and musical instruments, possessed the technical capability to manufacture the complex V8 design that Volvo had conceived. The collaboration leveraged Yamaha’s experience with high-performance engines whilst incorporating Volvo’s safety and durability requirements.

Yamaha’s involvement extended beyond mere manufacturing; the Japanese company contributed significantly to the engine’s design optimisation and production methodology.

The partnership represented a unique fusion of Scandinavian engineering philosophy with Japanese manufacturing precision, resulting in an engine that delivered both performance and reliability.

This collaboration model would later influence other automotive partnerships, demonstrating how specialised engine manufacturers could contribute to mainstream automotive production.

Cross-plane crankshaft design and All-Aluminium construction

The B8444S featured a sophisticated cross-plane crankshaft design that contributed to its distinctive exhaust note and smooth power delivery. Unlike the flat-plane crankshafts found in many European V8s, the cross-plane configuration provided better balance and reduced vibration, characteristics that aligned perfectly with Volvo’s emphasis on refinement and comfort. The crankshaft featured offset journals and was precision-balanced to minimise internal friction whilst maximising durability.

Construction utilised an all-aluminium block and cylinder heads, reducing weight by approximately 40% compared to equivalent cast-iron designs. The aluminium construction contributed significantly to the engine’s 420-pound dry weight , making it one of the lighter V8 engines available during its production period. The open-deck block design featured cast-iron cylinder liners for enhanced durability, whilst the aluminium heads incorporated four valves per cylinder with dual overhead camshafts.

Variable valve timing integration and fuel injection systems

Advanced engine management systems distinguished the B8444S from many contemporary V8 designs. The engine incorporated variable valve timing on both intake and exhaust camshafts, optimising power delivery across the rev range whilst improving fuel efficiency and emissions compliance. The system automatically adjusted valve timing based on engine load, throttle position, and operating temperature to maximise performance under varying driving conditions.

Fuel delivery utilised a sophisticated multi-port injection system with individual injectors for each cylinder. The high-pressure fuel rail system operated at precisely controlled pressures to ensure optimal fuel atomisation and combustion efficiency. Electronic engine management coordinated ignition timing, fuel delivery, and variable valve timing to deliver smooth power whilst meeting stringent emissions standards across multiple global markets.

Complete volvo V8 model catalogue by generation

The comprehensive catalogue of V8-equipped Volvo models encompasses just two primary vehicle lines, each offering multiple trim levels and configurations. Production spanned six model years for the XC90 (2005-2011) and four years for the S80 (2006-2010), with regional variations affecting specific features and availability. Understanding the complete model range requires examining each variant’s unique characteristics and market positioning.

First-generation XC90 V8 AWD models (2005-2014)

The Volvo XC90 V8 represented the flagship variant of Volvo’s groundbreaking luxury SUV, which had debuted in 2002 with five and six-cylinder engines. V8 production commenced for the 2005 model year, initially available in base V8 configuration before expanding to include V8 Sport and V8 R-Design variants. All V8 models featured standard all-wheel drive through Volvo’s advanced Haldex system, which automatically distributed power between front and rear axles based on traction conditions.

The base XC90 V8 included leather-appointed seating for seven passengers, dual-zone automatic climate control, and Volvo’s comprehensive safety suite featuring multiple airbags, stability control, and the innovative Roll Stability Control system. Standard equipment levels positioned the V8 models as premium offerings within the XC90 range , competing directly with luxury SUVs from BMW, Mercedes-Benz, and Audi. The V8 Sport added distinctive exterior styling elements, upgraded wheels, and enhanced interior appointments, whilst the R-Design variant incorporated sport-tuned suspension and aggressive visual enhancements.

S80 V8 executive saloon specifications and variants

The second-generation Volvo S80, launched for 2007, offered V8 power as the range-topping option in its executive sedan lineup. The S80 V8 delivered 315 horsepower, slightly more than the XC90 variant, thanks to optimised tuning for the lower-riding sedan platform. This power advantage, combined with the S80’s superior aerodynamics and reduced weight, resulted in notably better acceleration and fuel efficiency compared to the SUV variant.

Luxury appointments in the S80 V8 included premium leather upholstery, real wood interior trim, and advanced comfort features such as heated and ventilated front seats.

The S80 V8 represented Volvo’s most sophisticated expression of executive luxury, combining Scandinavian design philosophy with American-style V8 performance.

Optional equipment packages added features like adaptive cruise control, advanced audio systems, and Volvo’s pioneering Blind Spot Information System (BLIS), establishing the S80 V8 as one of the most technologically advanced sedans of its era.

XC70 V8 cross country estate performance features

Contrary to some historical records, Volvo never produced an XC70 variant equipped with the B8444S V8 engine. The XC70 Cross Country estate remained committed to Volvo’s traditional inline-five and inline-six powerplants throughout its production run. This decision reflected the XC70’s positioning as a lifestyle vehicle focused on efficiency and versatility rather than outright performance. The confusion may stem from the visual similarity between the XC70 and V70 models, both of which shared similar wagon profiles.

The XC70’s engine lineup during the V8 era consisted primarily of turbocharged five-cylinder engines and naturally aspirated inline-six options. These powerplants provided adequate performance for the XC70’s intended market whilst delivering superior fuel economy compared to V8 alternatives . The decision to exclude V8 power from the XC70 lineup demonstrated Volvo’s strategic focus on positioning the XC90 as their premium V8 SUV offering.

S60 V8 R-Design limited production models

Similar to the XC70, Volvo never offered the S60 sport sedan with V8 power during the B8444S engine’s production period. The first-generation S60, produced from 2000 to 2009, relied exclusively on turbocharged five-cylinder engines for its performance variants, including the high-performance R models. The confusion regarding S60 V8 models may arise from the later development of S60 race cars for the Australian V8 Supercars Championship, which utilised modified 5.0-litre versions of the Volvo V8.

The Australian Supercars project, undertaken by Polestar and Garry Rogers Motorsport between 2014 and 2016, featured purpose-built racing versions of the second-generation S60 powered by enlarged V8 engines producing up to 650 horsepower. However, these racing applications represented entirely different engines from the production B8444S and were never available in road-going vehicles.

V70 V8 estate wagon technical configurations

The Volvo V70 estate wagon, like its XC70 Cross Country sibling, never received V8 power during the B8444S engine’s production period. The second-generation V70, produced from 2007 to 2016, focused on efficiency and practicality rather than maximum performance. Engine options included turbocharged four and five-cylinder units, with later models transitioning to Volvo’s Drive-E four-cylinder architecture.

The absence of V8 power in the V70 lineup reflected Volvo’s strategic decision to concentrate V8 availability in their highest-margin, most premium models. This approach maximised the return on their substantial V8 development investment whilst maintaining clear product differentiation within the model range . The V70’s target market prioritised cargo capacity, fuel efficiency, and everyday usability over the performance credentials that V8 power would have provided.

V8 engine performance data and drivetrain integration

The integration of Volvo’s V8 engine into their existing drivetrain architecture required extensive engineering modifications and sophisticated electronic control systems. The collaboration between engine management, transmission control, and all-wheel drive coordination created a seamless driving experience that maintained Volvo’s reputation for refinement whilst delivering the performance expectations associated with V8 power. Understanding these technical achievements provides insight into why the Volvo V8 models earned recognition for their balanced performance characteristics.

315 horsepower output and 440 nm torque delivery

The B8444S engine delivered its maximum power output of 311-315 horsepower at 5,850 rpm, with peak torque of 325 lb-ft (440 Nm) available from 3,900 rpm. This power curve provided strong mid-range performance whilst maintaining refinement at higher engine speeds. The torque delivery characteristics proved particularly beneficial for the XC90’s towing applications, enabling the SUV to handle loads up to 5,000 pounds when properly equipped.

Fuel efficiency figures reflected the engine’s sophisticated design, with the XC90 V8 achieving EPA ratings of 15 mpg city and 22 mpg highway. The S80 V8 demonstrated slightly better efficiency at 16 mpg city and 24 mpg highway , benefiting from improved aerodynamics and reduced weight compared to the SUV variant. These figures represented competitive performance within the luxury V8 segment during the mid-2000s, when environmental concerns had not yet reached today’s prominence.

Aisin 6-speed automatic transmission compatibility

All V8-equipped Volvo models utilised the Aisin Seiki AWTF80-SC six-speed automatic transmission, specifically calibrated for the V8’s power and torque characteristics. This transmission featured adaptive shift logic that learned individual driving patterns and adjusted shift points accordingly. The system incorporated multiple driving modes, allowing drivers to select between comfort-oriented and performance-focused shift schedules.

The transmission’s torque converter featured a lock-up clutch that engaged across a wide range of operating conditions to improve fuel efficiency and reduce heat generation.

The sophisticated transmission control module coordinated seamlessly with the engine management system to optimise both performance and efficiency across all driving conditions.

Manual shift control through steering wheel-mounted paddles provided driver engagement when desired, whilst the automatic mode delivered smooth, imperceptible shifts under normal driving conditions.

Haldex All-Wheel drive system integration

The Haldex all-wheel drive system integrated with V8 models represented the fourth generation of this Swedish-developed technology, offering improved responsiveness and durability compared to earlier versions. The system operated as a front-wheel drive configuration under normal conditions, automatically engaging rear-wheel power when sensors detected front wheel slip or loss of traction. This approach optimised fuel efficiency whilst providing all-weather capability when required.

Electronic management systems coordinated Haldex operation with the vehicle’s stability control and traction management functions. The system could transfer up to 50% of available torque to the rear axle within milliseconds of detecting traction loss. Advanced sensors monitored wheel speeds, steering angle, and throttle position to predict traction requirements before wheel slip occurred , providing proactive rather than reactive all-wheel drive engagement.

Electronic stability programme and traction control calibration

Volvo’s Dynamic Stability and Traction Control (DSTC) system received specific calibration for V8 models to accommodate the increased power and torque output. The system incorporated Roll Stability Control (RSC) technology, which monitored the vehicle’s roll angle and rate of roll to detect potential rollover situations. When excessive roll was detected, the system automatically applied individual wheel brakes and reduced engine power to help maintain vehicle stability.

The integration of multiple stability systems created a comprehensive safety net that allowed drivers to access the V8’s performance potential whilst maintaining Volvo’s industry-leading safety standards. Traction control intervention was carefully calibrated to allow controlled wheel slip during acceleration whilst preventing excessive loss of traction that could compromise vehicle control or component durability.

Regional market availability and production numbers

Volvo’s V8 models achieved global distribution across multiple markets, though availability and specifications varied based on regional regulations and market preferences. The United States represented the largest market for V8 models, accounting for approximately 70% of total production. European markets showed more modest demand, reflecting that region’s preference for diesel engines and concerns about fuel consumption. The total production of V8-equipped Volvos remained relatively limited, contributing to their current status as sought-after collector vehicles.

Production figures for the XC90 V8 totalled approximately 50,000 units across all model years and variants. The S80 V8 saw significantly lower production numbers, with fewer than 15,000 units manufactured during its four-year production run. These limited production figures reflect both the premium positioning of V8 models and the relatively short production period before Volvo transitioned to their downsized engine strategy . Regional distribution patterns showed strong concentration in North American markets, where large-displacement engines faced fewer regulatory obstacles.

Market reception varied significantly between regions, with North American buyers embracing the V8 option as a natural progression for the luxury SUV segment. European customers proved more resistant to V8 adoption, preferring the fuel efficiency and lower taxation associated with smaller displacement engines. This regional preference pattern influenced Volvo’s subsequent decision to focus development resources on turbocharged four-cylinder engines rather than pursuing V8 evolution.

V8 engine maintenance requirements and common technical issues

Ownership of V8-equipped Volvo models requires understanding specific maintenance requirements and potential technical challenges associated with this unique powerplant. The

complexity of the B8444S engine design requires adherence to manufacturer specifications for optimal performance and longevity. Scheduled maintenance intervals for V8 models typically follow a more intensive schedule compared to Volvo’s four and six-cylinder engines, reflecting the increased complexity and performance demands of the eight-cylinder powerplant.

Oil change intervals for the B8444S engine should occur every 5,000 miles or six months under normal driving conditions, with more frequent changes recommended for severe operating environments. The engine requires 6.9 quarts of high-quality synthetic oil meeting Volvo’s specific viscosity requirements. Timing belt replacement represents the most critical maintenance procedure, requiring service every 75,000 miles or 7.5 years to prevent catastrophic engine damage from belt failure. The interference design of the B8444S means that timing belt failure will result in extensive internal engine damage.

Common technical issues affecting V8 models include premature wear of the variable valve timing components, particularly the cam gear assemblies that control intake and exhaust timing. These components typically require attention between 80,000 and 120,000 miles, with symptoms including rough idle, reduced power output, and increased fuel consumption. The all-aluminium construction, whilst reducing weight, can present challenges with thread integrity in high-stress mounting points, requiring careful attention during major service procedures.

Regular maintenance of the cooling system proves essential for V8 longevity, as the increased heat generation from eight cylinders places additional demands on coolant circulation and temperature management systems.

Electronic engine management issues can manifest as intermittent performance problems, often related to the sophisticated interaction between variable valve timing, fuel injection, and ignition systems. Diagnostic procedures for these issues typically require Volvo-specific diagnostic equipment and expertise in V8 engine management systems, making independent service more challenging compared to Volvo’s simpler engine designs.

Volvo V8 legacy and discontinuation analysis

The discontinuation of Volvo’s V8 engine program in 2011 marked the end of an ambitious but ultimately brief chapter in the company’s engineering history. Multiple factors contributed to this decision, including changing emissions regulations, shifting consumer preferences towards fuel efficiency, and Volvo’s strategic realignment under new ownership by Geely Holding Group. The global financial crisis of 2008-2009 also impacted luxury vehicle demand, reducing the economic justification for maintaining low-volume, high-complexity powertrains.

Environmental regulations played a crucial role in the V8’s demise, as increasingly stringent fuel economy standards and carbon dioxide emissions limits made large-displacement engines economically challenging to maintain in production. The development costs required to bring the B8444S into compliance with future emissions standards exceeded the projected revenue from the limited sales volumes V8 models achieved. This economic reality forced Volvo to redirect engineering resources towards more efficient powertrains that could meet regulatory requirements whilst serving broader market segments.

The strategic shift towards Volvo’s Drive-E engine family represented a fundamental change in the company’s powertrain philosophy. Rather than pursuing incremental improvements to large-displacement engines, Volvo chose to focus entirely on smaller, more efficient engines enhanced with turbocharging, supercharging, and hybrid technology. This approach aligned with global automotive trends and positioned Volvo as a leader in sustainable powertrain development rather than a follower in traditional performance metrics.

Today’s collector market for V8-equipped Volvo models reflects their rarity and unique position in automotive history. Values for well-maintained examples have shown steady appreciation, particularly for low-mileage S80 V8 models and XC90 V8 R-Design variants. The combination of limited production numbers, Volvo’s reputation for durability, and the distinctive character of these models creates strong interest among enthusiasts who appreciate their understated performance credentials.

The Volvo V8 legacy demonstrates how automotive manufacturers must balance engineering ambition with market realities, regulatory requirements, and strategic positioning in an increasingly competitive global marketplace.

Future automotive historians will likely view Volvo’s V8 program as a fascinating example of traditional performance engineering meeting the dawn of the electrification era. These models represent the final expression of Volvo’s willingness to compete directly with established luxury manufacturers on their own terms, using conventional large-displacement technology. The subsequent success of Volvo’s electrified powertrains validates the strategic decision to abandon V8 development, whilst the enduring appeal of V8 models confirms the engineering excellence achieved during their brief production period.

The influence of the B8444S engine extends beyond Volvo’s own applications, as the Noble M600 supercar’s continued use of modified versions demonstrates the fundamental soundness of the basic design. This ongoing application in high-performance vehicles provides validation of the engineering decisions made during the original development program, even as mainstream automotive applications have moved towards electrification and downsizing strategies that make future V8 development increasingly unlikely across the entire industry.